3D laser scanning is made for the food industry

3D laser scanning is ideally suited to the food industry in particular. A maze of installations, pipework and complex shapes can be mapped in full 3D in a very short time. The entire building, including all its installations, is captured in billions of accurate measurement points and transferred virtually to your office. And there is no need to visit the site again to take further measurements. You can measure all the dimensions in the viewer or draw them with the point cloud in your own design software.

Laser scanning originated in the food and petrochemical industries and it is here that the main developments in laser scanning hardware and software are still taking place. A 3D laser scan forms the basis of virtually all aspects of the food industry: safety surveys, data capture for design software, control and maintenance, for creating as-built drawings and 3D models and, of course, all design issues.

What is laser scanning?

A laser scanner is a measuring instrument which takes reflectorless measurements of objects at high speed. The measurement data created by a 3D scanner is known as a point cloud. The latest scanners have a scan speed of 1.000.000 measurement points per second and a resolution (or scan density) of 1 mm. Laser scanners create a very realistic picture of the actual situation. The device not only takes measurements, it also takes high-speed photos in order to give each measurement point the correct colour value. This rapidly creates a highly accurate picture of the object in its environment. Point clouds are often used to create 2D drawings, 3D models, simulations and clash detections.

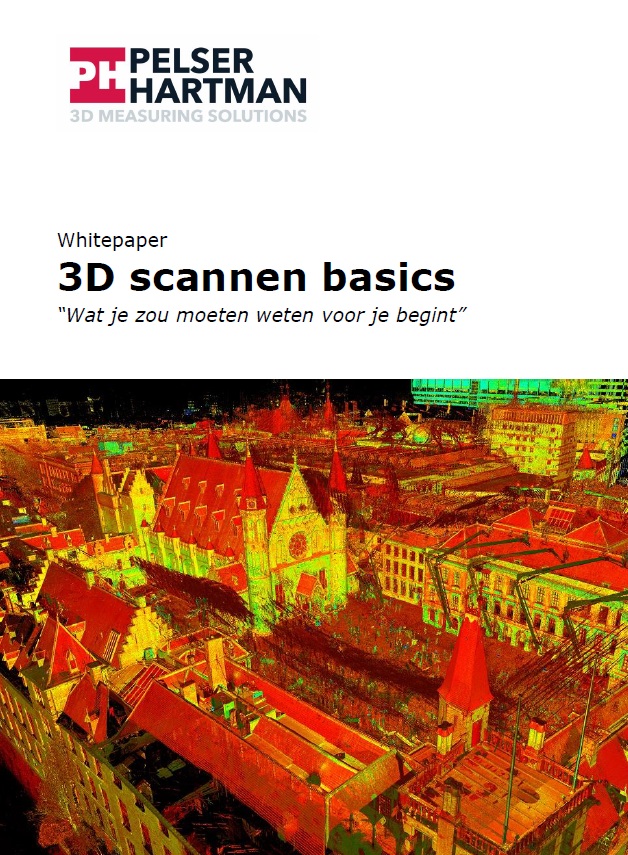

Picture: laserscandata or pointcloud in AutoCAD

Laser scanning is the only option!

In the food industry, conventional methods of surveying are generally a complete disaster.

Installations float in space, which makes it very difficult to determine their exact location. You have to get yourself into all sorts of tight spaces, between machinery and pipework, or work in dark rooms. It often takes hours. You have to take measurements at least three times: X, Y and Z. And even then, you’ll only have defined one point on a pipe. And, clearly, a tape measure or Disto would never work. What’s more, safety on the work floor is crucial in this industry. In many cases, there must be no contact with the installations and ladders and steps cannot be used. And putting scaffolding up everywhere is often impractical and expensive. 3D mapping of objects, rapidly, photorealistically and remotely, is the only way. That’s why the 3D laser scanner was invented.

3D design work and modelling by PelserHartman

PelserHartman provides a wide range of 3D laser scanning services. We scan structural objects and equipment and create 2D drawings and 3D models using special software. Clearly, we also supply point clouds and viewers which you can use to create models yourself. We can incorporate new elements (the design) into an existing situation. Potential clashes can then be detected on 3D elements and on the raw point cloud. That way, you can be certain that new parts will not impact on existing installations and structural components.

Point clouds can be used in an increasing range of software.

Examples of software packages that work with point clouds include:

- Autocad (full version)

- Inventor

- Revit

- Plant 3D

- Cyclone

- Aveva LFM

- PDMS

- Bentley

- Cloudworx

- CADWorx

- Sketchup Pro

We will be happy to advise you if you want to have a go at 3D design yourself!

3D viewers for the food industry

PelserHartman never supplies the point cloud without giving advice, and also offers customer support and training, where appropriate. The high-quality, customised data is delivered in a user-friendly format. Where companies do not want or are unable to design directly using point clouds, we can supply intermediate products or different types of viewers.

Picture: screenshot of viewer

We supply point clouds in various formats, specialised databases such as LFM for PDMS software, and various types of laser scan viewers, such as Leica Truviewer, Project-to-Go and Netview. If required, users can access the 3D files via the Internet or intranet. They can view the data, see all the technical issues and even measure complex distances!

High-end scanners for the food industry

The petrochemical and food industries have stringent requirements in terms of data quality. Safety and security are always top priority. A scanning project in these industries requires far more preparation time than usual, and completing all the safety and licensing procedures is a time-consuming business. All the more reason to choose the best equipment, which can take measurements in any conditions.

Most situations require an enclosed, phase-based, high-end 3D scanner where the quality of the hardware and scan data can be monitored. It is crucial to be able to adjust not only the resolution but also the quality of the data at all times. In the food industry, surfaces are often highly reflective or dark. That is why PelserHartman works with only the best equipment and always uses eye-safe scanners as standard.

General advantages of laser scanning

The advantages of 3D laser scanning are obvious: the device does not skip over things (miss anything out), does not require a light, can be positioned in awkward places and accurately measures all curved shapes. Details which may be required at a later stage, such as suspension systems, connections and concrete contours, can also be surveyed. It is also worth mentioning that, as well as the installations themselves, the scans capture the work space (the area round the installations). That way, the mechanic can see in advance how much space there is to work in. Access routes can also be captured in order to determine in advance whether new components can be installed in the desired location.

Conclusion:

For fast, error-free and accurate surveying of an existing situation in the food industry, 3D laser scanning is the only option!

More information:

For more information contact PelserHartman at our office in ’s-Hertogenbosch:

0031-(0)73-6135729.